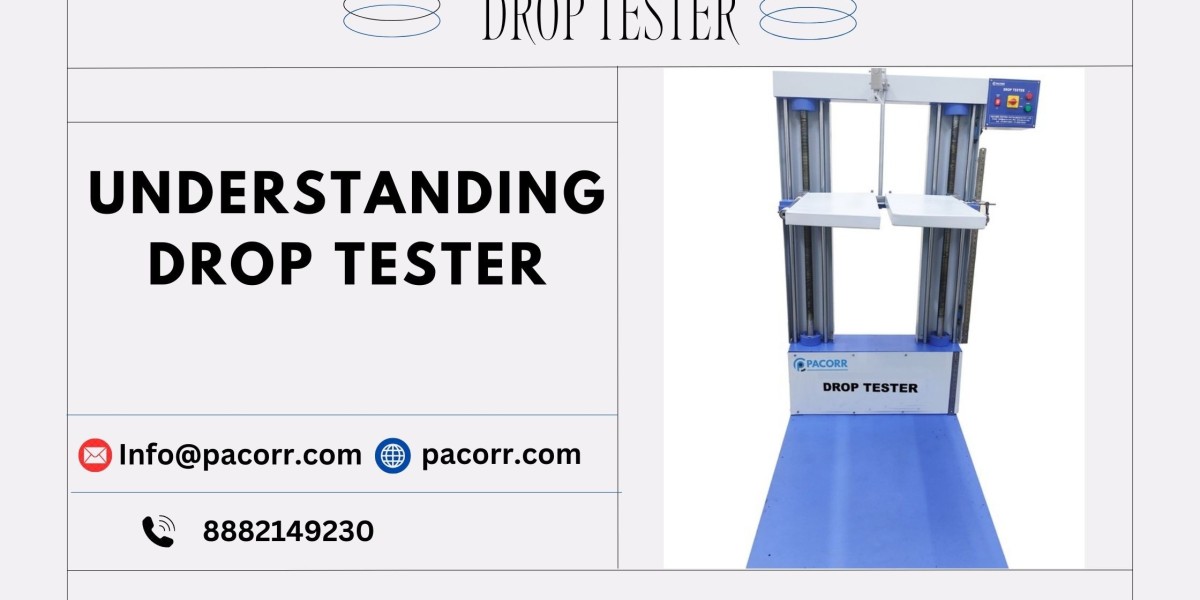

One tool that has become indispensable for such testing is the Drop Tester Price, a machine designed specifically to evaluate a product’s resilience to impacts from falls and drops. In this article, we’ll explore how drop testers work, why they’re crucial for quality assurance, and how companies across various industries can benefit from integrating these tools into their quality control processes.

What is a Drop Tester?

A drop tester is a mechanical device engineered to simulate drops and impacts that a product may experience during transportation or use. By using drop testing, manufacturers can assess how well a product can withstand accidental drops, helping to identify potential weaknesses or flaws before the product reaches consumers. Drop Tester come in various models to accommodate different testing needs, ranging from lightweight products like electronics to heavier goods such as industrial equipment.

How Does a Drop Tester Work?

A drop tester typically operates by placing the item being tested at a predetermined height and allowing it to drop onto a specified impact surface. Some drop testers are designed to release the item from a stationary height, while others offer multiple angles and heights to simulate different real-world conditions. The test item can be dropped multiple times, at varying heights, to thoroughly examine its durability and identify stress points.

Drop Test Equipment also offer programmable controls, which allow manufacturers to customize drop parameters such as height, angle, and surface type to match the conditions their product is likely to face. Some advanced models even record impact data, helping manufacturers analyze and interpret results with precision.

Key Benefits of Using a Drop Tester

- Enhanced Product Quality: Drop testing helps manufacturers refine their products, ensuring they can withstand common impacts. By identifying weaknesses early, businesses can improve product design, increase durability, and enhance customer satisfaction.

- Cost-Efficiency: Catching potential issues before a product hits the market helps companies avoid costly recalls or product failures, saving time and resources in the long run.

- Compliance with Standards: Many industries have strict standards and regulations for product durability. Using a drop tester allows companies to meet these standards confidently, ensuring compliance with safety and quality guidelines.

- Customer Satisfaction: Products that perform reliably over time build brand loyalty. Drop-tested products are more likely to withstand normal wear and tear, reducing the likelihood of returns and enhancing consumer trust.

Industries That Benefit from Drop Testing

Drop Tester Manufacturer has applications across a wide range of industries. Here are a few notable examples:

- Consumer Electronics: Phones, tablets, and laptops are vulnerable to accidental drops. Drop testers help manufacturers test these devices to withstand impacts, ensuring they remain functional after inevitable falls.

- Packaging: Packaging companies use drop testers to verify that their boxes, containers, and wraps can protect contents effectively during shipping and handling.

- Household Appliances: Items like kitchen appliances and small home devices go through drop testing to ensure they’re durable enough for regular use and minor mishaps.

- Medical Devices: Durability is crucial for medical devices, which are often used in critical environments. Drop testing ensures that medical equipment can endure routine handling without compromising performance.

- Automotive: Parts within cars, trucks, and motorcycles must remain intact during transit and under regular use. Drop testers help ensure the longevity of components in the automotive industry.

Selecting the Right Drop Tester for Your Business

Choosing the right Drop Tester Machine depends on various factors, including product weight, desired testing angles, and compliance requirements. Here are some essential considerations:

- Product Weight and Size: Ensure that the drop tester you select can handle your product’s weight and dimensions.

- Testing Options: Some products require more sophisticated drop testing, such as rotational drops or drops from varying angles. Choose a tester with programmable settings if your product demands more nuanced testing.

- Data Recording: Advanced drop testers can record impact forces and other critical data, which helps in analyzing and understanding the test results more accurately.

Conclusion

The role of a Drop Tester in quality assurance and product durability testing cannot be overstated. From consumer electronics to medical devices, these machines play a pivotal role in ensuring that products meet the durability expectations of consumers and industry standards. For businesses that prioritize quality and reliability, investing in a high-quality drop tester is a wise move that not only boosts customer satisfaction but also reinforces brand reputation in the competitive market.

Contact Us:

- Email: Info@pacorr.com

- Phone: 8882149230

- Visit our website at www.pacorr.com for more details on our testing instruments.